ErtelAlsop EA-Series Recessed Chamber Filter Presses

For industries requiring reliable liquid-solid separation, the ErtelAlsop EA-Series Filter Presses represent the gold standard in dewatering efficiency. Whether you are operating in mining, pharmaceuticals, food and beverage, or wastewater treatment, these recessed chamber presses are engineered to optimize filtration cycles and maximize cake dryness.

As a distributor for premium filtration solutions, Purecowater provides access to ErtelAlsop’s extensive line of filter presses. These units are designed to dewater solids into cakes of 25-60% total concentration, providing clearer filtrate solutions than systems that simply remove free water.

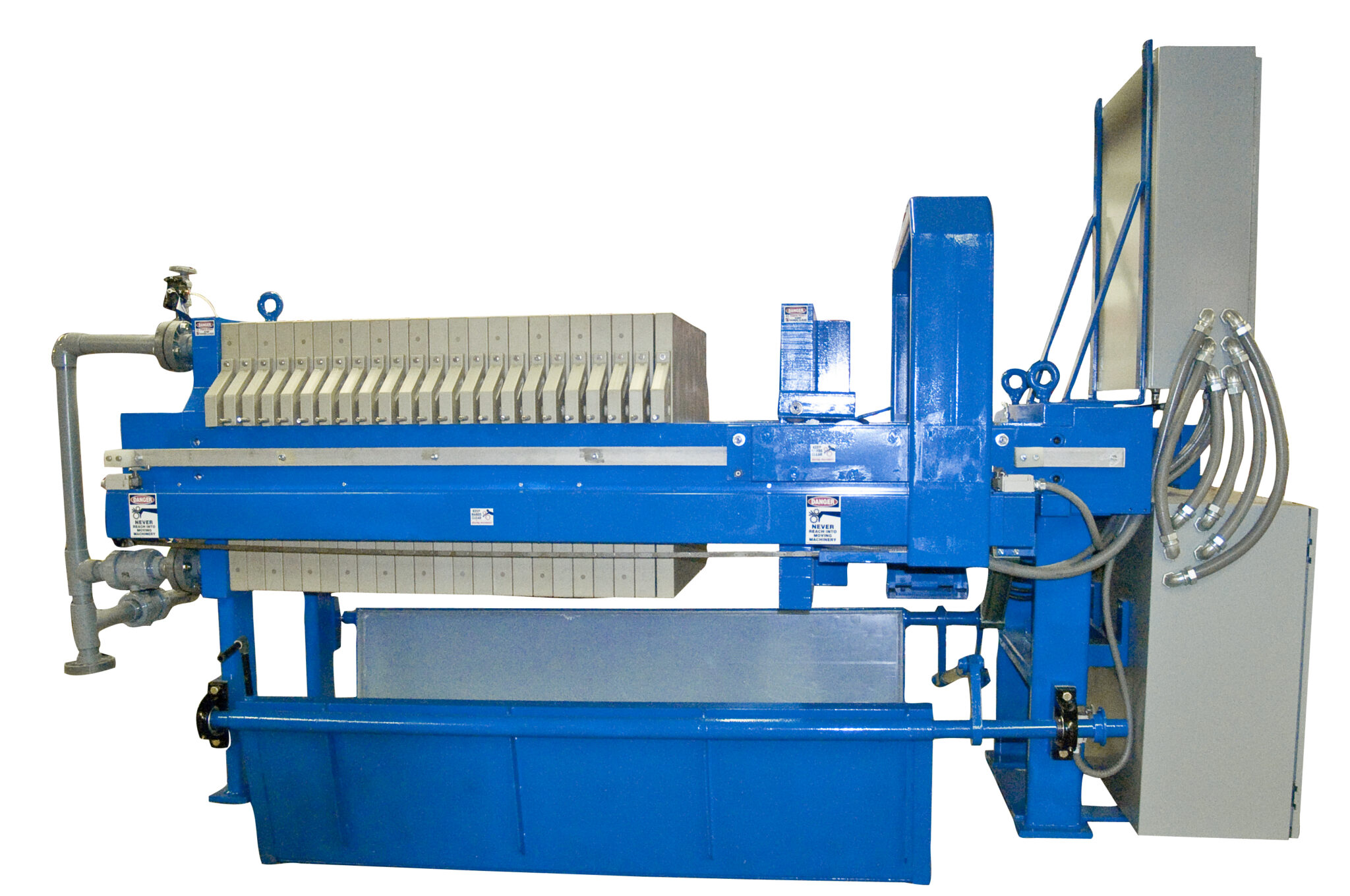

The heavy-duty EA-Series is designed for high-volume solid-liquid separation.

Overview of the EA-Series

The EA-Series is a line of Recessed Chamber Filter Presses that incorporates feedback from hundreds of operators to address common pain points in industrial filtration. Key design improvements include fast-acting hydraulic systems, uniform fill manifolds, and four-corner discharge porting to reduce cycle times.

Standard models feature 32mm gasketed polypropylene plates. Unlike non-gasketed alternatives, these plates ensure leak-free processing, which is critical for handling hazardous materials or valuable product streams. The skeleton is constructed from high-strength carbon steel with chemically resistant paint, ensuring longevity even in harsh environments.

Product Specifications and Lineup

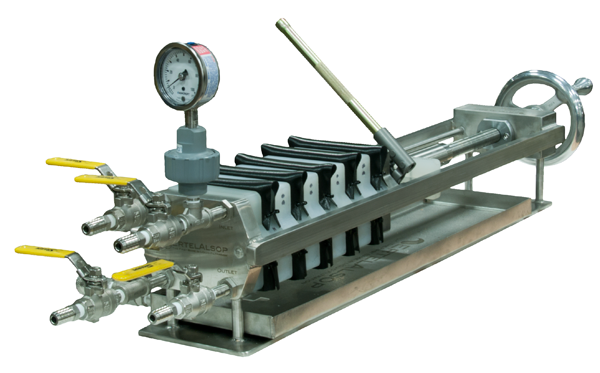

ErtelAlsop offers a wide range of sizes to suit everything from laboratory testing to large-scale industrial processing. Below is a breakdown of the available models and their capacities.

| Model | Scale | Solids Capacity (Cu. Ft.) | Primary Application |

|---|---|---|---|

| EA-102 | Lab / Pilot | 0.01 – 0.05 | Testing, Scale-up, Small Batches |

| EA-203 | Lab / Pilot | 0.03 – 0.29 | Process Development, Small Volume |

| EA-470 | Industrial | 0.5 – 2.9 | Production Dewatering |

| EA-630 | Industrial | 2.9 – 10.0 | Mid-Size Processing |

| EA-800 | Large Scale | 10 – 30 | High Volume Sludge/Solids |

| EA-1000+ | Large Scale | 20 – 300 | Municipal, Mining, Heavy Industry |

The EA-470 is ideal for processes requiring 0.5 to 2.9 cubic feet of solids handling.

Key Features and Benefits

The EA-Series is built to reduce operational costs while improving safety and filtrate quality.

- Leak-Free Processing: Standard 32mm gasketed plates (CGR) prevent leakage during the filtration cycle, ensuring a clean operating environment.

- High Compaction Pressure: Capable of compressing solids into cakes with 25-60% concentration, significantly reducing waste volume compared to systems that only remove free water.

- Robust Construction: Skeleton made of high-strength carbon steel with 304 stainless steel side bar wear strips for durability.

- Flexible Automation: Available with manual hydraulic closures or fully electric hydraulic systems with PLC controls for automated operation.

- Expandability: Many frames are designed with expansion capability, allowing you to add plates as your production volume increases.

Standard vs. Optional Configurations

Every application has unique requirements. While the standard configuration covers most dewatering needs, ErtelAlsop presses can be customized with various features.

| Standard Features | Optional Features |

|---|---|

|

• 32mm Gasketed Polypropylene Plates • Hydraulic Closure System • High Strength Carbon Steel Skeleton • Schedule 80 PVC Head Connections • Alternating Discharge (1B & 3B) • Chemically Resistant Paint • 304 SS Side Bar Wear Strips |

• Membrane / Squeeze Plates • Automatic Plate Shifters • Safety Light Curtains & Lanyards • Cake Carts or Chutes • Stainless Steel or Aluminum Manifolds • Bombay Doors (Drip Trays) • PLC Control Integration |

Common Applications

The versatility of the EA-Series makes it a preferred choice across diverse sectors:

- Biomass & Dewaxing: Efficient removal of lipids and polishing of dissolved Oleoresin. Capable of filtering solvents at extremely low temperatures (-40°F).

- Breweries (Mash Filtration): Replaces traditional lauter tuns to separate wort from grain solids in minutes rather than hours. The result is faster production, reduced water usage (up to 40% less), and drier grain for disposal.

- Distilleries: Used for processing still mash, allowing for the recycling of effluent (backset) and reducing waste disposal costs.

- Municipal Wastewater: High-volume sludge dewatering to minimize hauling and disposal fees.

- Mining & Minerals: Efficient tailings dewatering and precious metal recovery.

The EA-102 model is perfect for laboratory testing and scale-up studies.

Why Choose ErtelAlsop?

ErtelAlsop engineers work closely to design the optimum piece of equipment for specific applications, focusing on cycle optimization, cost reduction, and safety. Their presses are not just off-the-shelf units but are often tailored to specific operating conditions—whether that involves high temperatures, aggressive chemicals, or sanitary requirements.

If you are looking to improve your liquid-solid separation process, reduce waste volume, or recover valuable filtrate, the EA-Series is a proven solution.

Need help sizing a filter press for your facility?

Contact Us to Get Started