High-Efficiency Liquid-Solid Separation with ErtelAlsop EA Series

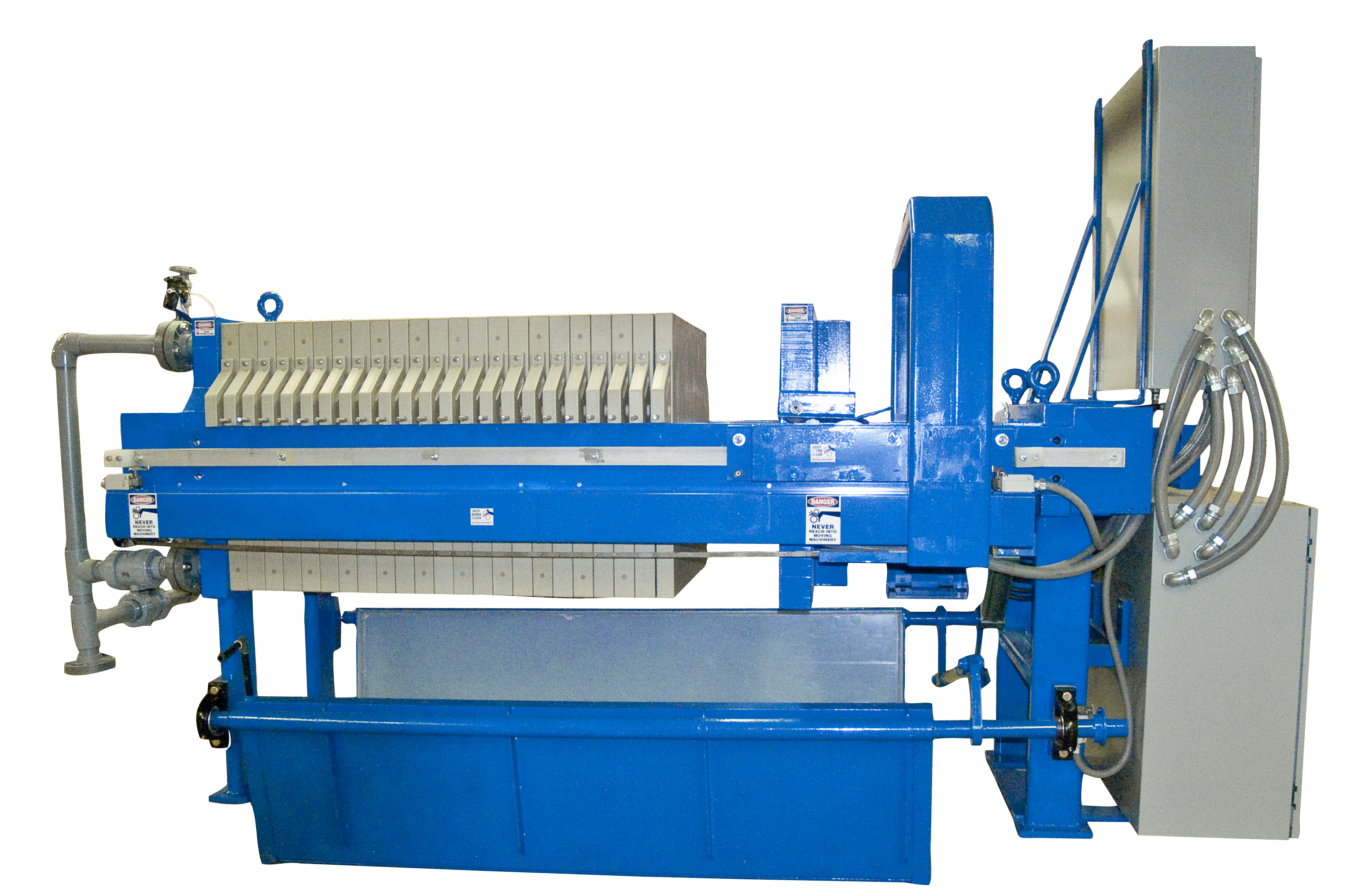

For industries requiring rigorous liquid-solid separation and sludge volume reduction, ErtelAlsop Recessed Chamber Filter Presses (EA Series) represent a gold standard in filtration technology. As a distributor for premier filtration solutions, Purecowater provides these advanced systems to helping facilities achieve drier filter cakes, clearer filtrate, and optimized cycle times.

Unlike simple filtration methods that only remove free water, the EA Series utilizes high compaction pressure to dewater solids into cakes ranging from 25% to 60% total concentration. This makes them an ideal solution for wastewater treatment, chemical processing, food and beverage production, and pharmaceutical applications.

What is a Recessed Chamber Filter Press?

The recessed chamber filter press is an evolution of the traditional plate and frame design. In this configuration, the filter plates themselves have a recessed area on both sides that forms the filtration chamber when the plates are clamped together.

Key Advantages of the Design:

- Leak-Free Processing: The EA Series utilizes 32mm gasketed polypropylene plates as a standard. This ensures a tight seal, crucial for hazardous or high-value liquid processing.

- High Compaction: The hydraulic closure system applies significant pressure, forcing slurry into the chambers and capturing solids on the filter media while clear filtrate passes through.

- Efficiency: Designed for “batch” processing, these units minimize cycle downtime with features like discharge alternating porting (1-button / 3-button) and uniform fill manifolds.

Product Specifications and Capacities

The EA Series is scalable from laboratory testing to large-scale industrial dewatering. Whether you are scaling up a new product or managing municipal sludge, there is a model sized to fit the flow rate and solids holding capacity you need.

Model Capacity Guide

| Model Series | Application Scale | Solids Capacity (cu. ft.) | Typical Use Case |

|---|---|---|---|

| EA-102 | Laboratory | 0.01 – 0.05 | R&D, Feasibility Testing |

| EA-203 | Laboratory / Pilot | 0.03 – 0.29 | Scale-up, Small Batches |

| EA-470 | Production | 0.5 – 2.9 | Small Process Lines |

| EA-630 | Production | 2.9 – 10.0 | Mid-Size Dewatering |

| EA-800 | Industrial | 10 – 30 | Chemical, Mining |

| EA-1000 | Industrial | 20 – 60 | Wastewater, Large Chemicals |

| EA-1200 / 1500 | Heavy Duty | 40 – 300+ | Municipal, Large Mining |

Standard vs. Optional Features

Every ErtelAlsop press is built on a chemically resistant painted steel skeleton designed for durability. Below is a breakdown of the configuration options available through Purecowater.

| Standard Features |

|

| Optional Upgrades |

|

Who uses the EA Series Filter Press?

Because filter presses rely on pressure rather than gravity or vacuum, they are versatile across many sectors.

- Chemical Manufacturing: Ideal for recovering high-value solids (e.g., precious metals) or clarifying liquid products.

- Breweries & Distilleries: Used for mash filtration to separate wort from grain solids efficiently, replacing traditional lauter tuns for faster processing.

- Industrial Wastewater: Reducing sludge volume from metal finishing or remediation reduces disposal haul-off costs significantly.

- Biomass & Dewaxing: Capable of filtering solvents at low temperatures (-40°F) for lipid removal and biomass separation.

Why Choose ErtelAlsop Through Purecowater?

As a distributor for ErtelAlsop, Purecowater ensures you get the exact configuration for your process. The EA Series stands out because it allows for expansion capability. A press frame can often be purchased with a removable spacer, allowing you to add more plates later as your production volume grows without buying a new machine.

Get a Quote or Technical Consultation

Do you need assistance sizing a recessed chamber filter press for your solid-liquid separation needs? Our team can help you select the right plate material, cake thickness, and automation level.