ErtelAlsop plate and frame filter presses represent the industry standard in depth filtration and liquid-solid separation. Designed for versatility and efficiency, these units are critical for applications ranging from pharmaceutical processing to food and beverage production. This overview details the technical specifications, operational benefits, and diverse configurations available to meet specific filtration requirements.

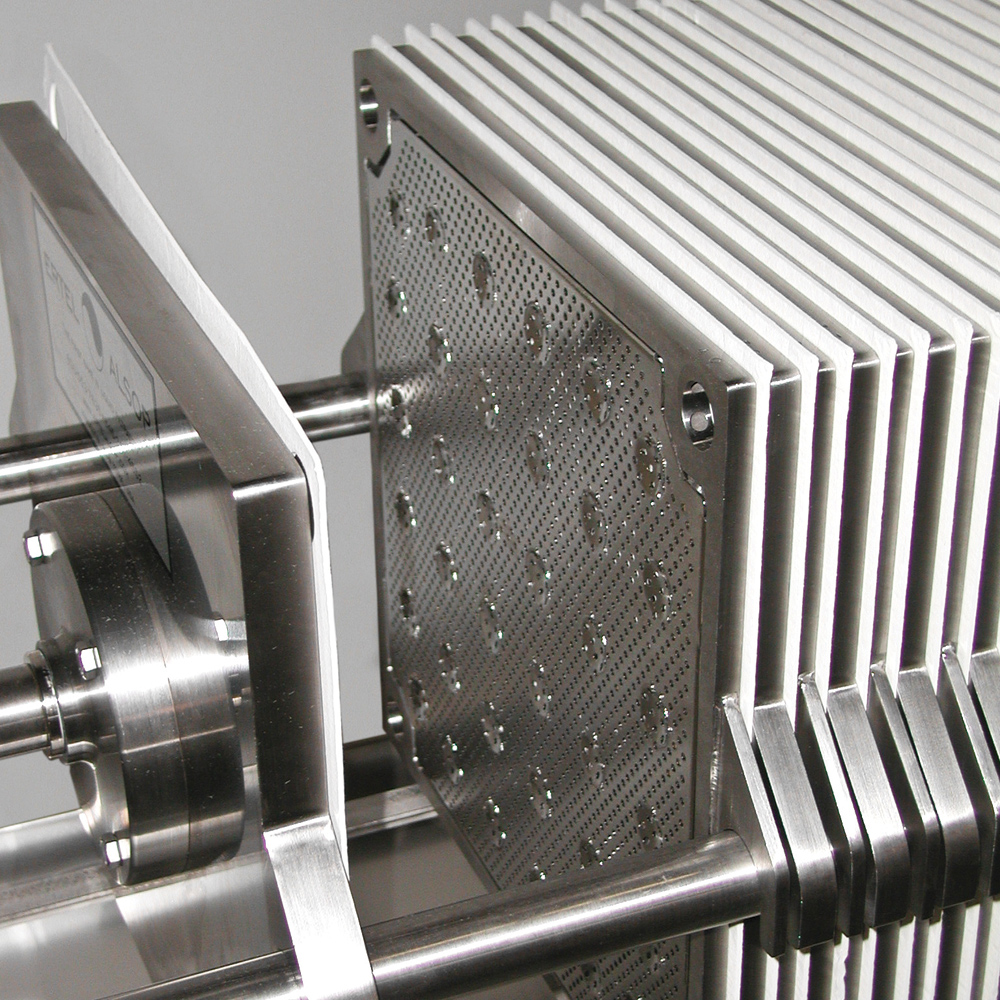

Core Technology: The Internally Ported Design

One of the distinguishing features of ErtelAlsop’s plate and frame filters is the internally ported design. Unlike external porting, which relies on multiple gaskets and external piping, the internal ports allow the filter media itself to act as the gasket [ertelalsop.com]. This engineering choice offers several operational advantages:

- Sanitary Operation: Eliminates cross-contamination risks associated with O-rings and gaskets that retain product residue.

- Cost Efficiency: Removes the need to purchase and replace expensive gaskets.

- Media Versatility: Accept a broad range of media materials and thicknesses, including pads, paper, and cloth.

Series Configuration and Specifications

ErtelAlsop offers distinct series tailored to different batch sizes and operational scales. Below is a breakdown of the primary product lines available.

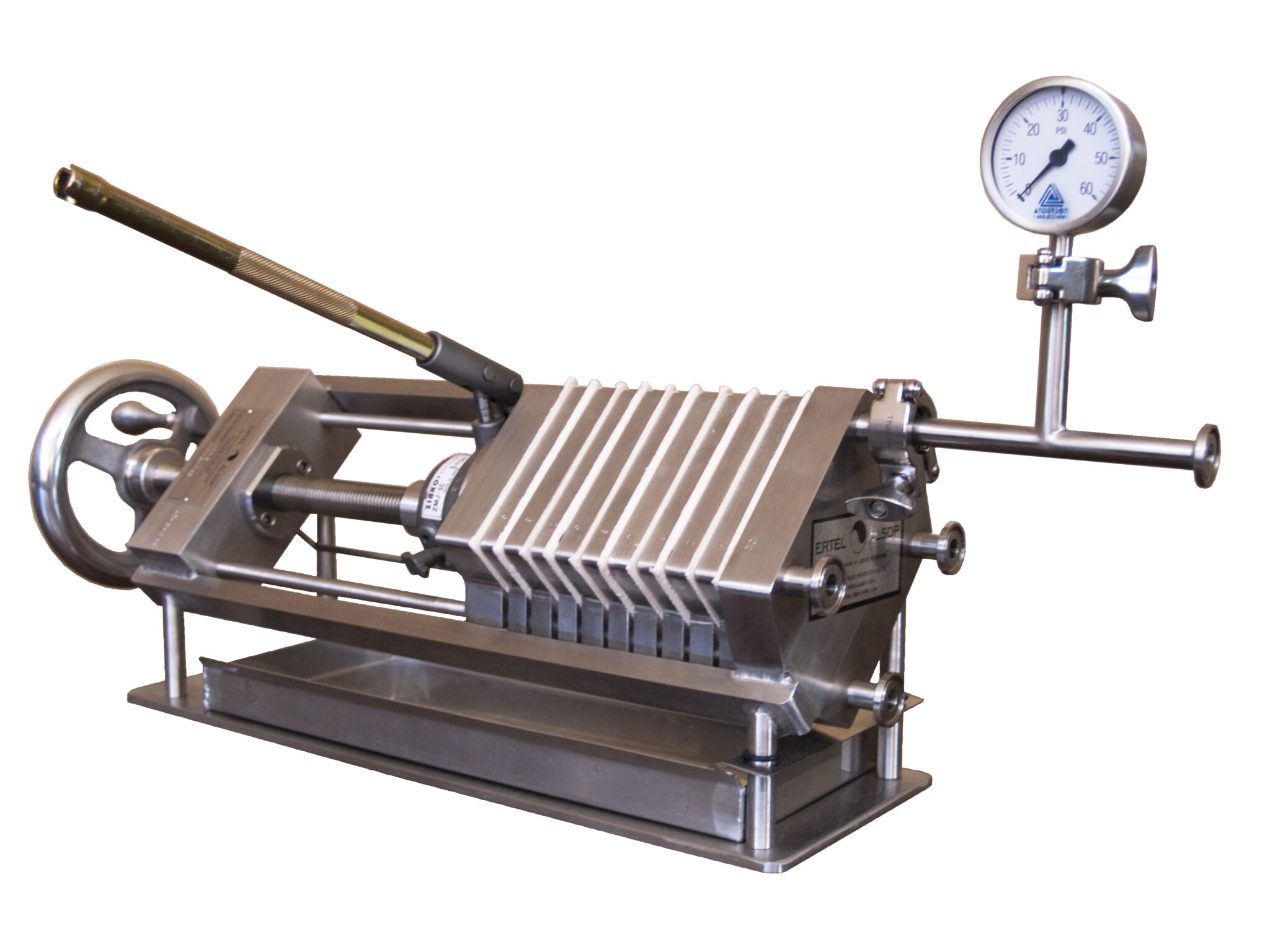

1. Diamond Series (Laboratory and Pilot Scale)

The Diamond Series is designed for critical applications, R&D, and small-batch processing where minimizing hold-up volume is essential. These units feature weld-free construction and BioClean™ outlet plates, making them ideal for pharmaceutical and high-purity applications [ertelalsop.com].

| Model | Plate Size | Pad Capacity | Key Feature |

|---|---|---|---|

| 4D | 4-inch square | Up to 20 pads | Smallest full press, Bench Top |

| 8D | 8-inch square | Up to 20 pads | No gaskets required, High efficiency |

| 12D | 12-inch square | Up to 50 pads | Cart-mounted, excellent scale-up |

2. Letre Series (Large Volume Production)

For large-scale industrial filtration, the Letre Series (24″ and 36″) is the industry standard. These filters enable large cake accumulation, allowing for longer filtration cycles and efficient cake washing for product recovery [ertelalsop.com].

| Specification | Letre 604 | Letre 910 |

|---|---|---|

| Plate Dimension | 24 in (610 mm) | 36 in (914 mm) |

| Filtration Area per Sheet | 3.6 ft² (0.33 m²) | 7.26 ft² (0.67 m²) |

| Flow Rate | Up to 50 gpm (190 lpm) | Up to 50 gpm (190 lpm) |

| Cake Volume (50mm inlet) | 3.98 gal (15.06 L) | 9.62 gal (36.40 L) |

3. EA Series (Recessed Chamber – Dewatering)

The EA Series Recessed Chamber Filter Presses are engineered for high-pressure dewatering applications, producing solids cakes of 25-60% concentration. These are distinct from standard plate and frame filters as they utilize recessed polypropylene plates for volume reduction of sludge and solids [ertelalsop.com].

- Applications: Dewaxing, Biomass Filtration, Mash Filtration, Waste Water.

- Size Range: From laboratory scale (EA-102) to large volume (EA-1500) handling nearly 300 cubic feet of solids.

Primary Applications and Industries

ErtelAlsop filters are utilized across a wide spectrum of industries due to their adaptability and high sanitary standards.

- Pharmaceuticals: Sterile filtration, removal of activated carbon, and small volume parenterals. BioClean plates ensure validation compliance.

- Food & Beverage: Clarification of spirits, wine, and fruit juices. Syrup filtration and removal of haze.

- Cosmetics & Fragrances: Haze removal in perfumes, colognes, and essential oils. Wax and lipid removal for product stability.

- Chemical: Production of polymers, surfactants, and specialty ingredients.

Technical Advantages Overview

Implementing an ErtelAlsop system provides tangible operational benefits:

- Low Cost of Ownership: The lowest cost of filtration per unit of fluid processed compared to other depth filtration methods.

- Product Recovery: The ability to wash the filter cake within the frame allows for the recovery of valuable liquid product that would otherwise be lost.

- Scalability: Lab results from the Diamond Series can be directly scaled up to production-level Letre Series presses.

- Vapor-Tight Options: For hazardous or volatile applications, the Vapor-Master enclosed design provides a sealed environment.

To determine the correct ErtelAlsop configuration for your specific solid/liquid separation challenges, or to discuss sizing and media compatibility: