Optimizing Filtration with ErtelAlsop MicroCap Capsules

In the demanding worlds of biopharmaceuticals, food and beverage production, and chemical processing, consistency and scalability are paramount. Purecowater is proud to distribute ErtelAlsop MicroCap™ Capsules, a premier solution for single-use depth filtration. Designed to seamlessly bridge the gap between laboratory research and full-scale production, these capsules offer efficiency without the need for complex cleaning validations.

Whether you are clarifying cell cultures or decolorizing spirits, the MicroCap line provides a versatile, disposable option that ensures product purity while streamlining your workflow.

What Are MicroCap Capsules?

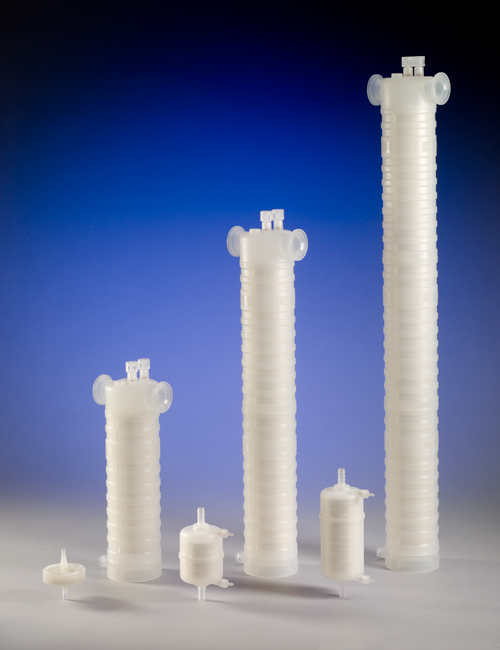

The MicroCap™ and MicroCap Pro™ series are single-use depth filter capsules that eliminate the need for stainless steel housings and the associated cleaning steps. They utilize ErtelAlsop’s high-performance filter media encapsulated in a robust polypropylene shell. This design minimizes operator exposure to fluids and dramatically reduces change-out times.

This technology is specifically engineered for linear scalability. The filtration performance you achieve with a small lab capsule (22.5 cm²) can be directly scaled up to production capsules (up to 2,800 cm² per capsule or larger assemblies) without revalidating the filtration media performance.

Key Features and Benefits

- Completely Disposable: No stainless steel housing required, eliminating cleaning validation (CIP/SIP) and reducing cross-contamination risks.

- Linear Scalability: Confidently scale from effective filtration areas (EFA) of 22.5 cm² up to production volumes.

- Low Hold-Up Volume: Designed to minimize product loss and reduce post-use rinsing volumes, ensuring high yield recovery.

- High-Quality Media: Incorporates ErtelAlsop’s renowned Micro-Media®, XL Series, and Micro-Clear™ carbon media.

- Pharmaceutical Grade: Materials meet USP Class VI testing and are safe for biopharmaceutical applications.

Technical Specifications

To help you select the right configuration for your process, review the specifications below. The MicroCap series is flexible, offering various connections and media types to suit specific fluid characteristics.

| Feature | Specification Details |

|---|---|

| Capsule Material | Polypropylene (USP Class VI) |

| Filter Media Options |

Micro-Media®: Cellulose & DE/Perlite XL Series: High Purity Celpure® DE Micro-Clear™: Immobilized Activated Carbon |

| Available Surface Areas |

Lab Scale: 22.5 cm², 550 cm², 1,100 cm², 2,200 cm² Production Scale (Pro): Customizable large-scale assemblies |

| Max Operating Pressure | Typically up to 30-45 PSI (dependent on model) |

| Connection Styles | Sanitary Clamp, Hose Barb, Luer LoC (for small laboratory units) |

Filter Media Formulations

The core power of the MicroCap lies in the media inside. Depending on your removal requirements, you can choose between several high-performance options:

- Micro-Media® (Cellulose/DE): Excellent for general clarification. It utilizes high zeta potential to capture particles smaller than the mechanical pore structure. Ideal for haze removal and protein clarification.

- XL Series (Celpure® DE): Uses high-purity Diatomaceous Earth. This series provides extremely high throughput and robust retention, often exhibiting 2-5 times the throughput of competitive media.

- Micro-Clear™ (Activated Carbon): Contains immobilized activated carbon. This is the cleanest way to utilize carbon for decolorization or endotoxin removal without dealing with the mess of loose carbon powder.

Common Applications

The MicroCap capsules are widely used across industries where purity and efficiency are non-negotiable.

- Biopharmaceuticals: Mammalian cell culture clarification, removal of cell debris, and vaccine production.

- Blood Fractionation: Clarification of plasma proteins and serum.

- Food & Beverage: Decolorization of spirits, flavor clarification, and haze removal in syrups.

- Cosmetics: Filtration of oils, fragrances, and active ingredients.

Start Your Project with Purecowater

Implementing ErtelAlsop MicroCap capsules can reduce your downtime and improve the consistency of your filtration batches. As a distributor for ErtelAlsop and other leading filtration brands, Purecowater can help you identify the precise media grade and capsule size for your specific flow rate and retention needs.

For inventory inquiries, technical data sheets, or to request a quote, please reach out to our team.