Overview: Advanced Depth Filtration for Critical Applications

The ErtelAlsop Micro-Media® series represents a high-performance standard in depth filtration. Unlike standard cellulose media, Micro-Media® sheets are engineered composites formulated with cellulose pulp, filter aids (such as Diatomaceous Earth or Perlite), and a wet strength resin. This unique composition makes them the go-to solution for applications requiring high retention efficiency, superior clarity, and significant solids loading capacity.

Purecowater is proud to distribute ErtelAlsop solutions, helping industries ranging from pharmaceuticals to food and beverage solve their toughest liquid filtration challenges.

The Zeta-Potential Advantage

A defining feature of the Micro-Media® series is the incorporation of wet strength resins that impart a positive charge, known as Zeta-Potential, to the filter matrix. This electrokinetic charge allows the filter to attract and retain negatively charged contaminants (like bacteria, endotoxins, and colloidal haze) that are even smaller than the physical pore size of the media.

Product Series & Composition

ErtelAlsop Micro-Media® is not a “one-size-fits-all” product. It is available in distinct series, each tailored to specific regulatory and process requirements.

| Series | Composition | Key Application / Benefit |

|---|---|---|

| Micro-Media® (Standard) | Cellulose + DE/Perlite + Resin | General clarification for Food & Beverage, Chemicals, and Cosmetics. |

| XL Series™ | Cellulose + Celpure® (High Purity DE) + Resin | Critical Biopharma applications. Ultra-low extractables and low beta-glucan content. |

| L Series | High Purity Cellulose + Resin | Reduced false positives in LAL tests; ideal for protein solutions. |

| LXL Series | High Purity Cellulose + Celpure® DE | The ultimate in purity: combined benefits of XL and L series for sensitive biologics. |

| PXL Series | Double Layer Media (P200 Web Complex) | High solids loading capacity. Bioprocessing workhorse for cell harvesting and debris removal. |

Technical Specifications & Grades

Micro-Media® sheets are customized by grade to provide precise retention ratings, from coarse clarification down to microbial reduction.

| Grade Name | Retention Rating (Approx.) | Typical Application |

|---|---|---|

| M-104 | 10.0 µm | Wine clarification, syrup polishing, coarse filtration. |

| M-404 | 5.0 µm | Polishing spirits, haze removal in juices. |

| M-454 | 2.5 µm | Bio-burden reduction, pre-filtration for membranes. |

| M-504 / M-504T | 1.0 µm / 0.8 µm | Fine polishing, removal of fine particulates. |

| M-704 | 0.45 µm | Microorganism reduction, yeast removal in wine. |

| M-854 | 0.3 µm | Critical final filtration, enzyme solutions (Microbial Reduction). |

Key Benefits

- Compliance: Use of materials listed in CFR 21 as generally recognized as safe (GRAS) for food contact.

- Sterilization: Wet strength resins allow the media to be steam sterilized or autoclaved without structural failure.

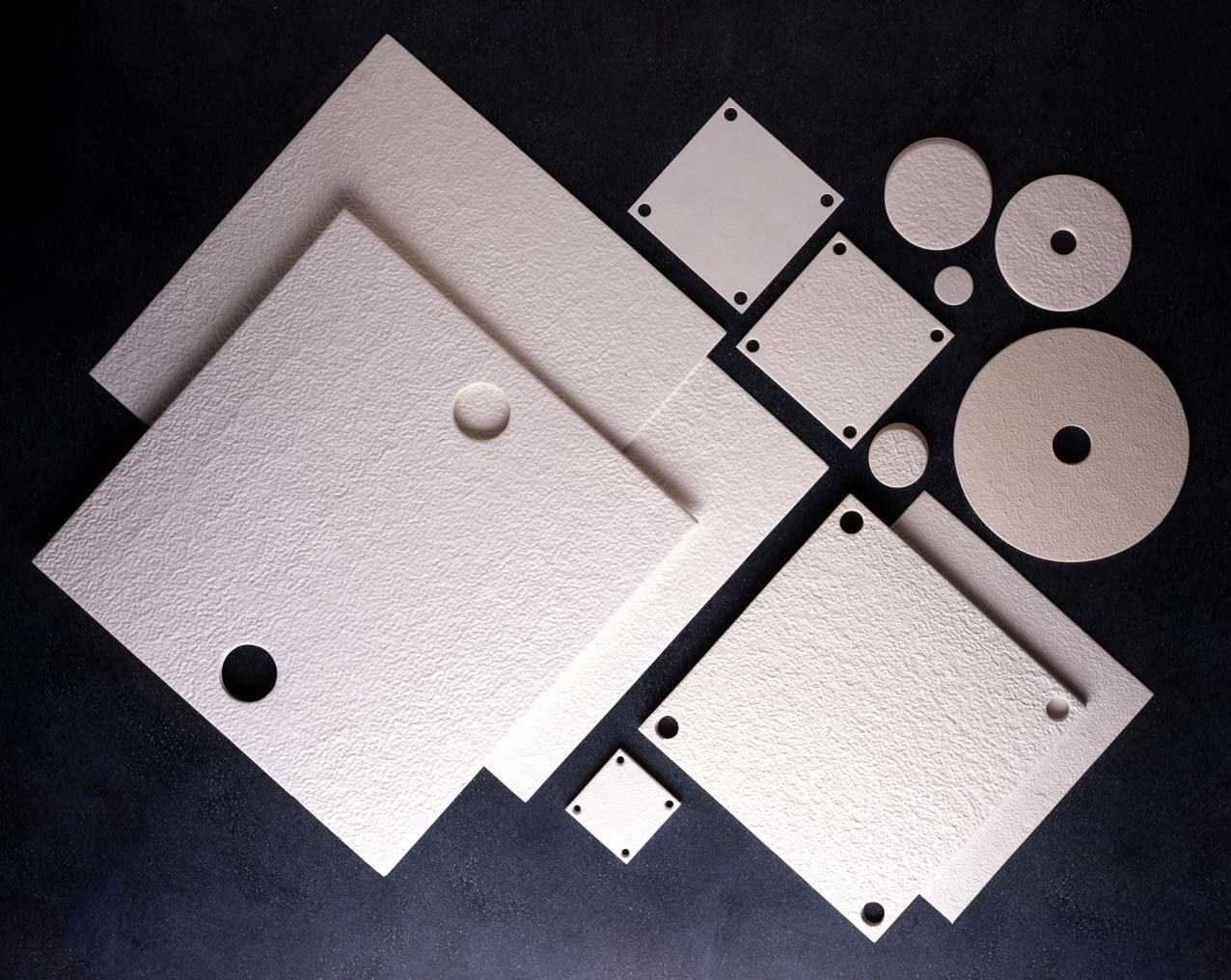

- Versatility: Suitable for flat sheets, lenticular cartridges (Pak®), and various custom geometries.

- Efficiency: High surface area and internal matrix volume offer superior throughput compared to surface filtration.

Applications

ErtelAlsop Micro-Media® is a staple across various industrial sectors:

- Pharmaceuticals: Upstream processing, cell harvesting, blood fractionation, and API filtration. The XL and LXL series are specifically designed to meet USP Class VI standards and minimize extractables.

- Food & Beverage: Haze removal in beer and wine, clarification of fruit juices, sugar syrups, and removal of fine particulates in distilled spirits.

- Cosmetics & Utilities: Purification of fragrances, essential oils, and dielectric oils.

Need to optimize your depth filtration process with the correct Micro-Media grade?

Purecowater can assist with sizing, grade selection, and distribution.