Introduction to Pilot Scale Filtration

For industries ranging from pharmaceuticals to mining, the gap between laboratory testing and full-scale production can be a canyon of uncertainty. The ErtelAlsop AccuScale Pilot Scale Filter Press (specifically the EA-Series Lab Presses) bridges this gap, providing precise, scalable data that ensures your full-scale filtration system performs exactly as predicted.

Purecowater is proud to distribute ErtelAlsop’s line of pilot-scale filter presses, designed specifically for new product development, batch testing, and process scale-up. These units—most notably the EA-102 and EA-203—replicate the mechanics of large-scale recessed chamber presses in a compact, bench-top format.

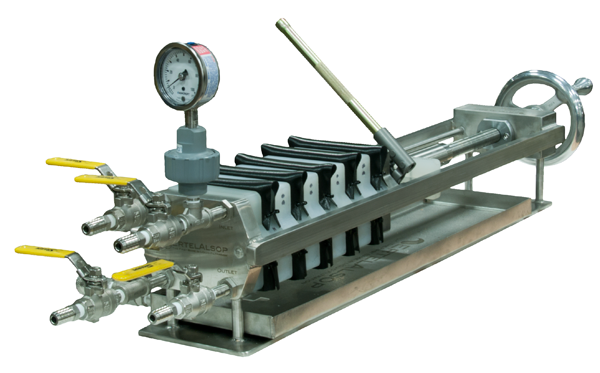

The EA-102 Lab Filter Press: A compact powerhouse for feasibility testing.

What is the AccuScale Pilot Filter Press?

The AccuScale (EA-Series) pilot presses are high-compaction liquid-solid separation devices. Unlike simple funnel tests, these machines use pressure filtration to compress solids into filter cakes with 25-60% total concentration [ertelalsop.com]. This capability allows engineers to determine cake dryness, filtrate clarity, and cycle times accurately before investing in large capital equipment.

Who is this for?

- R&D Laboratories: For testing new chemical formulations or biomass extractions.

- Process Engineers: To validate upscale parameters for wastewater or production streams.

- Small Batch Manufacturers: Ideally suited for high-value biologicals, pharmaceuticals, or essential oils where batch sizes are small (0.01 to 0.3 cubic feet).

Key Models and Specifications

The AccuScale line is anchored by two primary models: the 4-inch (102mm) EA-102 and the 8-inch (203mm) EA-203. Both are engineered with the same robust features as ErtelAlsop’s large industrial presses.

EA-102: The Laboratory Standard

The EA-102 is the smallest unit, perfect for feasibility studies where sample volume is limited. It allows for quick cloth or paper changeovers, making it highly versatile for multi-product labs.

| Specification | Value |

|---|---|

| Plate Size | 102 mm (approx. 4 inches) |

| Solids Capacity | 0.01 – 0.05 cu. ft. |

| Standard Cake Thickness | 32 mm |

| Framework Material | Chemically Resistant Painted Carbon Steel |

| Closure System | Manual Hydraulic |

EA-203: The Pilot Workhorse

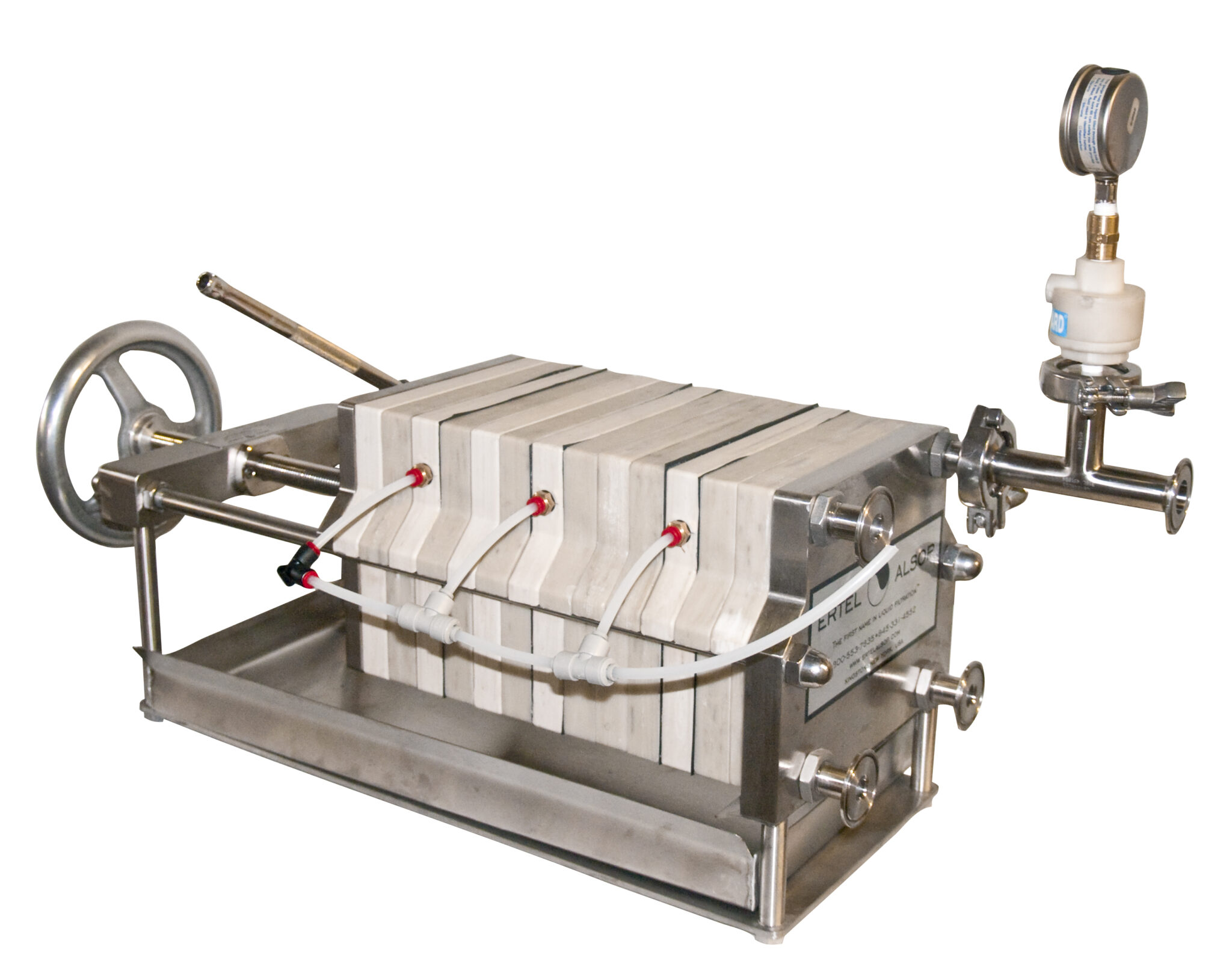

The EA-203 steps up significantly in capacity, filling the potential gap between bench-top and small production. It is large enough to simulate production dynamics, including cake washing and squeezing.

The EA-203 Model features increased capacity and optional membrane squeeze plates.

| Specification | Value |

|---|---|

| Plate Size | 203 mm (approx. 8 inches) |

| Solids Capacity | 0.03 – 0.29 cu. ft. |

| Standard Connections | Schedule 80 PVC (Optional: Stainless, Aluminum) |

| Wear Strips | 304 Stainless Steel Side Bar Wear Strips |

| Max Operating Pressure | 100 psi (Standard) to 225 psi (High Pressure) |

Features That Drive Performance

ErtelAlsop incorporates features into these pilot units that are usually reserved for massive industrial presses. This “AccuScale” philosophy means the data you get is the data you can trust.

- Robust Skeleton: High-strength carbon steel skeletons ensure safety and durability under high hydraulic pressures [pdf.directindustry.com].

- Leak-Free Operation: Standard 32mm caulk and gasketed polypropylene plates prevent leakage, crucial for hazardous or high-value fluids.

- Plate Versatility: Can be configured with Recessed Chamber, Membrane Squeeze, or Plate and Frame designs depending on the application flexibility required.

- Expansion Capability: These units often feature movable head plates or expansion spacers, allowing the filtration volume to grow as your testing needs evolve.

Detail of the hydraulic closure and plate stack on an EA-203 unit.

Applications

The versatility of the ErtelAlsop pilot series makes them suitable for a diverse set of industries:

- Pharmaceuticals: Clarification of cell cultures and recovery of active pharmaceutical ingredients (APIs).

- Food & Beverage: Filtration of syrups, flavors, fragrances, and small-batch spirit production.

- Mining & Aggregates: Testing tailings dewatering and precious metal recovery rates [ertelalsop.com].

- Chemical Processing: Dewatering hazardous sludges or recovering solvents in a closed-loop system.

Why Choose ErtelAlsop for Pilot Testing?

Choosing an ErtelAlsop press through Purecowater means investing in reliability. These units are manufactured in the United States and come with a 6-year unconditional warranty on the press frames [pdf.directindustry.com]. Whether you are running a single feasibility test or continuous pilot batches, the EA-Series provides the mechanical stability and filtration accuracy needed to make informed process decisions.

Ready to Scale Up Your Filtration Process?

Contact Purecowater today to discuss your specific suspended solids, cake capacity needs, and to get a quote on the ErtelAlsop AccuScale Pilot Press.