Continuous Filtration with the Eaton HYD DU 63 Duplex Filter

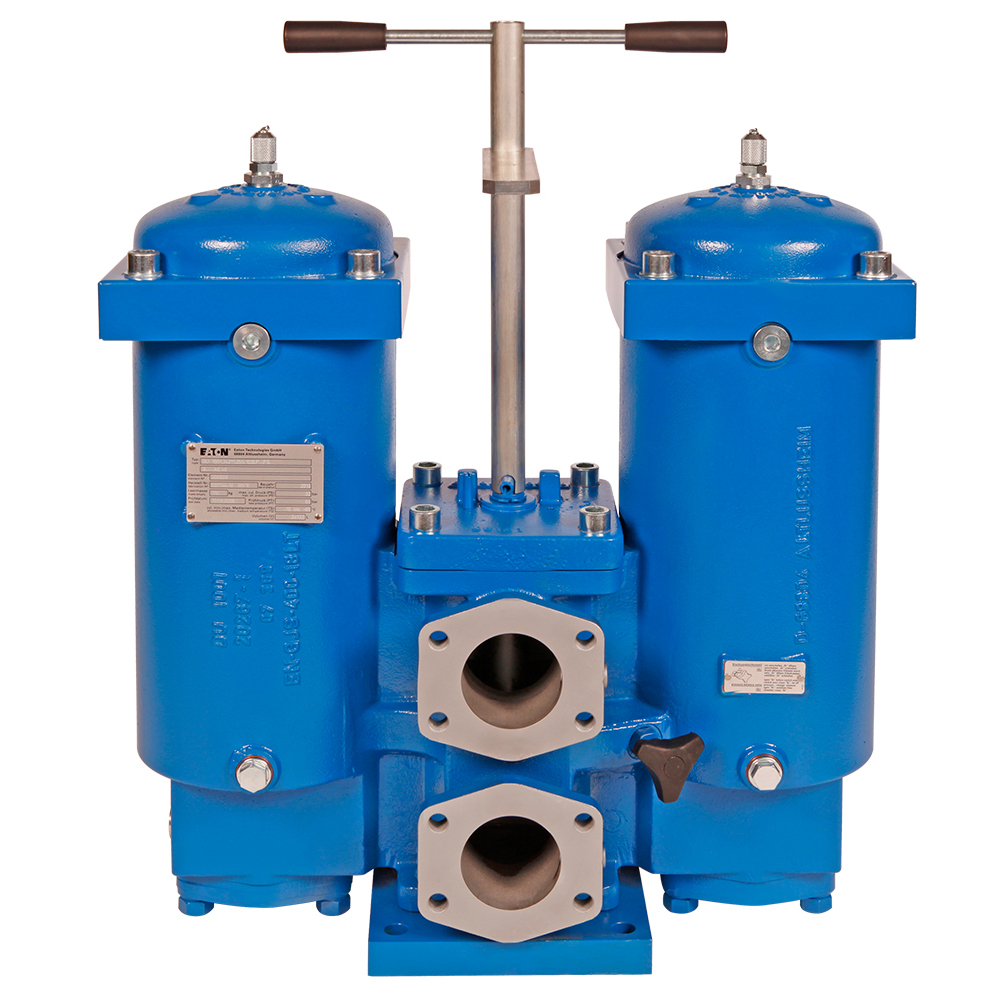

In industrial hydraulic and lubrication systems, downtime is the enemy of productivity. The Eaton HYD DU 63 is a low-pressure duplex filter designed specifically to solve this problem. By integrating two filter housings with a three-way changeover valve, this unit allows for the replacement of clogged filter elements without ever shutting down the system.

As a distributor for premium filtration solutions, Purecowater provides the Eaton DU series to facilities requiring high operational continuity, such as power generation turbines, large gearboxes, and critical hydraulic circuits.

What is the Eaton DU 63?

The Eaton DU 63 is an in-line, duplex pressure filter capable of handling operating pressures up to 63 bar (914 psi). It is designed for mounting in suction, pressure, or return lines. Is primary feature is the integrated changeover valve, which directs fluid flow through one filter chamber while the other is isolated. This design enables maintenance personnel to service the dirty element while the system remains live and protected.

The filter elements used in the DU 63 utilize star-shaped pleated material, maximizing surface area for high dirt-retaining capacity. This ensures a long service life and reduces the frequency of maintenance cycles.

Key Technical Specifications

The DU 63 is engineered for versatility across various fluid types and operating conditions. It supports petroleum-based fluids, HW-emulsions, water glycols, and most synthetic lubrication fluids.

| Specification | Details |

|---|---|

| Series | DU (Duplex Pressure Filter) |

| Nominal Size | 63 |

| Max Operating Pressure | Up to 63 bar (914 psi) |

| Operating Temperature | 14°F to 176°F (-10°C to +80°C) |

| Flow Direction | Outside to Inside |

| Valve Type | Three-way changeover valve |

| Housing Material | Aluminum or Carbon Steel component mix (dependent on model) |

| Sealing Material | Nitrile (NBR) or Viton (FPM) |

Features and Benefits

- Zero Downtime: The primary advantage of the DU 63 is the ability to switch filter sides. When the pressure drop indicator signals a clogged element, the operator simply turns the handle to the clean side, isolating the dirty side for easy removal.

- High Intrinsic Stability: Eaton filter elements are bonded to the end caps with high-quality adhesive and supported by a perforated core tube, ensuring they can withstand pressure peaks with a sufficient safety margin.

- Versatile Media Options:

- Wire Mesh (G): Cleanable stainless steel mesh (nominal rating).

- Microglass (VG): Disposable, multi-layer glass fiber fleece for high-efficiency filtration (finer than 40 μm).

- Paper (P): Standard filtration paper.

- Safety: Designed to absorb pressure peaks effectively, protecting downstream components like valves and bearings from catastrophic failure.

Primary Applications

The Eaton HYD DU 63 is widely used in industries where fluid cleanliness is critical for equipment longevity. Common applications include:

- Lubrication Systems: Protecting bearings in steam and gas turbines.

- Hydraulic Power Units: Ensuring clean oil in continuously running manufacturing presses.

- Gearboxes: Filtering oil in wind turbine or industrial drive gearboxes.

- Test Stands: maintaining fluid purity during component testing.

Maintenance and Element Replacement

Maintenance on the DU 63 is safe and straightforward. Once the changeover valve has diverted flow to the clean chamber, the dirty side is depressurized. The cover can be removed, and the element lifted out. For wire mesh elements, cleaning is possible, though microglass elements should always be replaced to ensure consistent ISO cleanliness codes.

Get a Quote for Eaton Filtration Solutions

Purecowater is your trusted source for Eaton filtration products, including the DU 63 Duplex Filter. Whether you need a complete housing assembly or replacement elements, our team can help you select the exact specifications for your fluid type and pressure requirements.