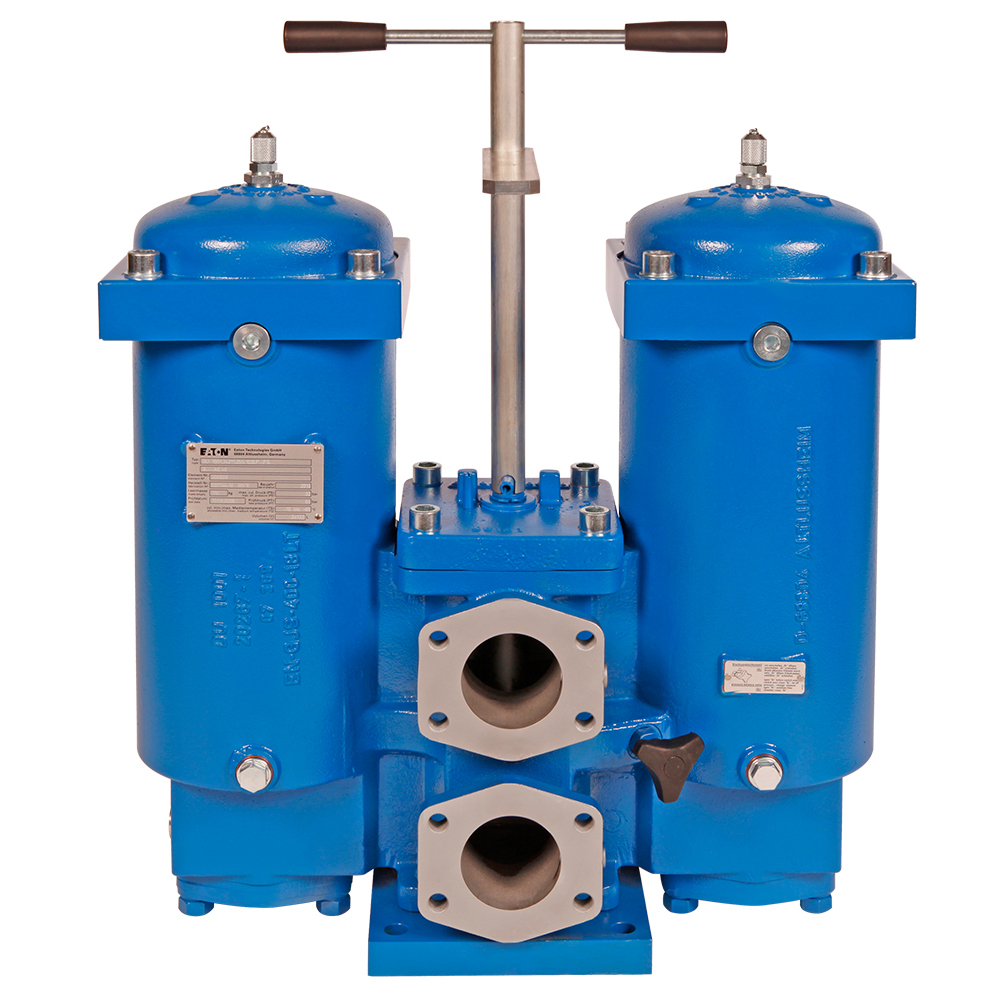

Continuous Hydraulic Filtration with Eaton DU 101-401 Duplex Filters

For industrial hydraulic and lubrication systems, downtime is often not an option. The Eaton DU 101-401 series of duplex low-pressure filters is engineered specifically for applications requiring 24/7 continuous operation. By utilizing a dual-chamber design with an integrated changeover valve, these filters allow maintenance teams to replace dirty filter elements without shutting down the system or interrupting the flow of fluid.

Purecowater supplies the full range of Eaton filtration solutions, including the robust DU 101, DU 251, and DU 401 models, helping industries maintain cleaner fluids and extend the life of critical machinery.

What is the Eaton DU 101-401 Series?

The Eaton DU series consists of inline-mounted duplex filters designed for operating pressures up to 464 psi (32 bar). They are typically installed in suction, pressure, or return lines to protect components from particulate contamination. The range specifically covering DU 101 through DU 401 offers a compact yet high-capacity solution for medium-flow applications.

The core innovation in this series is the three-way changeover valve located in the center of the housing. This valve ensures pressure balance during switching, making the transition from the contaminated “dirty” side to the clean standby side smooth and safe.

Key Features and Benefits

- Zero Downtime: The duplex capability allows for element changes during operation.

- High Intrinsic Stability: Designed to absorb pressure peaks with a sufficient safety margin.

- Versatile Compatibility: Suitable for mineral oils, H-W emulsions, and most synthetic hydraulic fluids.

- Integrated Safety: Includes a pressure balance valve to prevent hydraulic shock during changeover.

- Maintenance Indicators: Available with visual and electrical clogging indicators to signal improved timing for element replacement.

Technical Specifications

The DU 101-401 models are built for reliable performance in harsh industrial environments. Below are the general specifications for this range:

| Specification | Details |

|---|---|

| Max. Operating Pressure | 464 psi (32 bar) |

| Operating Temperature | -10°C to +80°C (+14°F to +176°F) |

| Filter Material | Glass fiber fleece (VG), Stainless steel wire mesh (G) |

| Retention Rating | Down to 10 µm (ISO) or finer depending on element |

| Housing Material | Aluminum or Nodular Cast Iron (EN-GJS-400-18-LT) |

| Mounting Position | Vertical (Inline) |

| Connections | Threaded or Flanged (SAE/ANSI) options available |

Primary Applications

Due to their rugged construction and high dirt-holding capacity, Eaton DU filters are widely used across various heavy industries. They are particularly effective in protecting sensitive downstream components such as servo valves and bearings.

- Power Generation: Turbine lubrication systems.

- Machine Tools: Hydraulic power units for presses and molding machines.

- Marine & Offshore: Steering gear hydraulics and deck machinery.

- Mining & Steel: Gearbox lubrication and heavy-duty hydraulic lines.

Why Choose Eaton DU Filters?

The Eaton DU series stands out because of its efficient flow path and low pressure drop. The housings are designed to minimize turbulence, ensuring that the fluid passes through the filter media evenly. This maximizes the effective surface area of the filter element, leading to longer intervals between changes and lower total cost of ownership.

Additionally, the option for various sealing materials (Nitrile, Viton) allows these filters to be customized for specific fluid chemistries, ensuring compatibility with your existing process fluids.

Need Assistance with Eaton Filtration?

Purecowater is your trusted partner for Eaton filtration solutions. Whether you need a new DU series installation or replacement elements for your existing housing, our team is ready to assist you.