Industrial liquid-solid separation requires robust, continuous filtration media capable of withstanding harsh chemical environments and abrasive slurries. Clear Edge Filtration filter belts are engineered to meet these rigorous demands across mining, chemical processing, and wastewater treatment sectors. Purecowater supplies these high-performance technical fabrics to help facilities optimize throughput and reduce maintenance downtime.

This article details the specifications, applications, and distinct advantages of Clear Edge’s primary filter belt lines: Horizontal Vacuum Filter Belts, Press Belts, and Vertical Tower Press Belts.

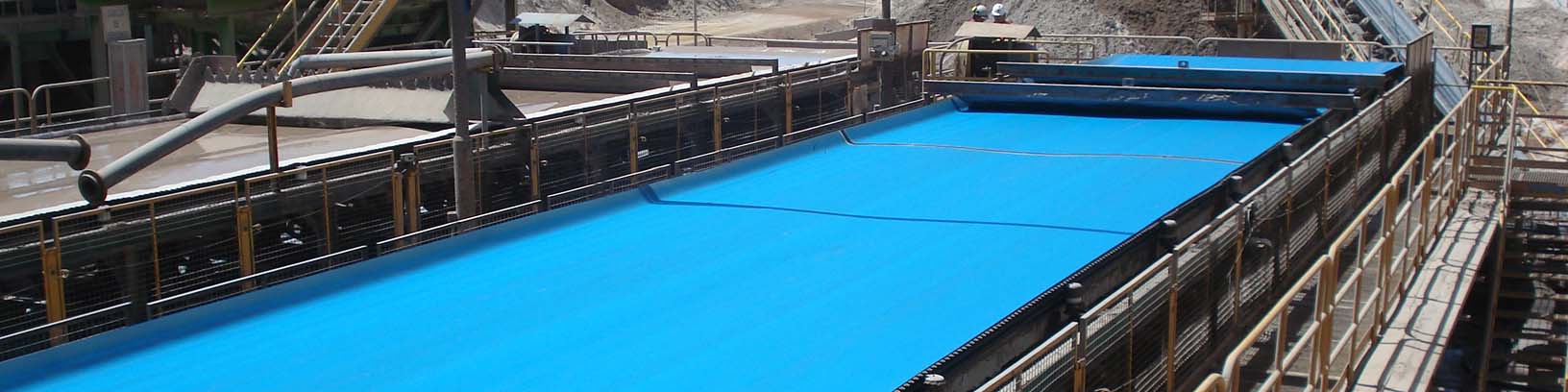

Horizontal Vacuum Filter Belts

Horizontal Vacuum Filter Belts (HVBF) are designed for continuous processing where visibility and ease of monitoring are critical. These belts utilize a vacuum mechanism beneath the fabric to separate liquids from solids as the slurry travels toward the discharge end.

Clear Edge engineers these belts to handle high flow rates and abrasive conditions found in sectors like Mining and Minerals, Phosphate processing, and Flue Gas Desulfurization (FGD) [clear-edge.com].

Key Features and Abra-Seal™ Technology

A common failure point in horizontal belts is the seam, where turbulence and abrasive particles can cause leakage and premature wear. Clear Edge utilizes Abra-Seal™ Seam technology, which incorporates a low-profile impermeable sealing panel. This proprietary shield protects the clipper seam from centrifugal abrasive action, significantly extending belt life compared to conventional velcro or cloth flaps.

| Specification | Details |

|---|---|

| Industry Applications | Mining, Chemicals, Power Generation, Food & Beverage |

| Filtration Mechanism | Vacuum-assisted continuous belt |

| Seaming Options | Clipper seams, Abra-Seal™ protected seams |

| Compatible OEMs | Andritz, FLSmidth, WesTech, Eimco, Pannevis |

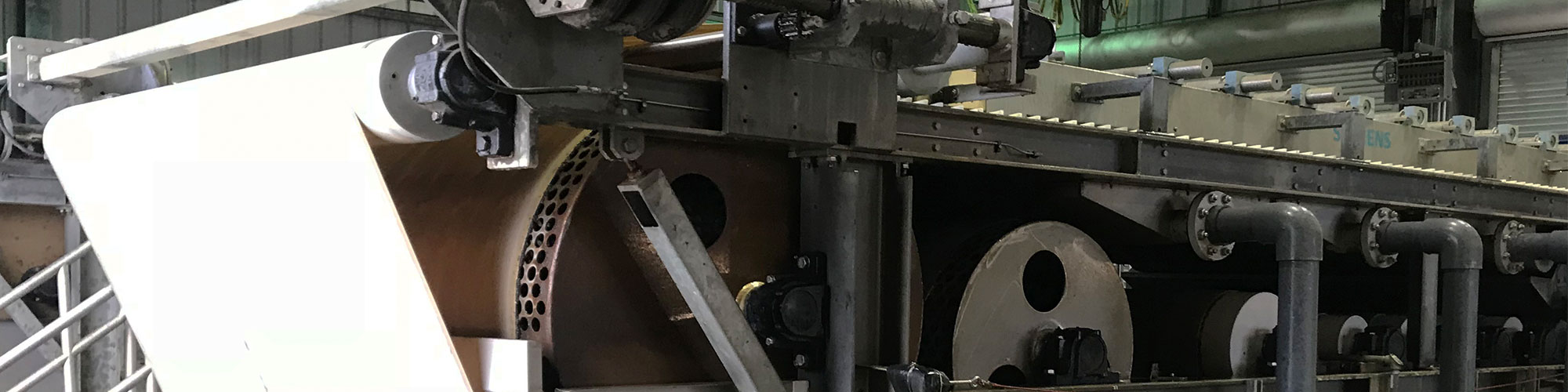

High-Performance Press Belts

For applications requiring multi-stage dewatering, such as municipal wastewater treatment and pulp recycling, Press Belts are the industry standard. These systems function by sandwiching the slurry between two moving belts and guiding it through a series of rollers. The pressure forces liquid out, leaving a filter cake that is collected at the end of the machine.

Clear Edge Press Belts are constructed from varying weaves of polypropylene and polyester to ensure high filtration efficiency and resistance to “blinding” (clogging) [clear-edge.com].

Operational Advantages

- High Throughput: Designed for continuous operation in high-volume environments.

- Smooth Cake Release: Engineered surfaces ensure the dewatered cake drops cleanly, reducing cleaning time.

- Dimensional Stability: Polyester and PP blends prevent the belt from stretching or shrinking under tension.

Vertical Tower Press Belts

Vertical Tower Presses are utilized when a facility has limited floor space but requires extremely dry filter cakes. These belts operate in high-pressure environments and are critical for industries like pigments, dyes, and pharmaceuticals.

Clear Edge Vertical Tower Press Belts are available for 1.05m and 1.7m machines. They feature sealed, reinforced edges to withstand the high mechanical stress of vertical indexing and pressure filtration [clear-edge.com].

Comparison of Filter Belt Technologies

Choosing the right belt depends on the specific moisture content goals and available footprint. The table below outlines the primary differences between the three main belt types:

| Feature | Horizontal Vacuum Belt | Press Belt | Vertical Tower Press Belt |

|---|---|---|---|

| Primary Action | Vacuum extraction | Roller pressure (Sandwich) | High-pressure chamber |

| Key Industries | Mining, Phosphoric Acid | Municipal Wastewater, Paper | Fine Chemicals, Pigments |

| Performance Goal | Continuous high flow | Sludge volume reduction | Maximum dryness / Cake washing |

Material Science: Yarn and Weave

The longevity of a filter belt is dictated by its material composition. Clear Edge employs specific yarn types to match the chemical acidity or alkalinity of the process fluid.

- Polypropylene (PP): Excellent chemical resistance and smooth surface for cake release. Common in standard water and acid applications.

- Polyester (PET): Superior tensile strength and resistance to stretching. Used where belt tension is a critical factor.

- Weave Patterns: Spiral and woven designs are available to optimize the balance between drainage speed and particle retention [clear-edge.com].

Contact Purecowater for Filtration Solutions

Whether you require replacement belts for a belt press, vacuum filter, or tower press, selecting the correct technical fabric is essential for process efficiency. Purecowater can assist in identifying the optimal Clear Edge specification for your equipment.