For industries requiring precise solid-liquid separation and superior depth filtration, ErtelAlsop Plate and Frame Filters represent a standard of excellence. Known for their robust construction and economic efficiency, these filters are designed to handle applications ranging from small pharmaceutical batches to large-scale chemical processing.

At Purecowater, we understand that selecting the right filtration equipment is critical for operational success. This overview details the capabilities, specifications, and advantages of the ErtelAlsop Plate and Frame Filter line.

The Internally Ported Advantage

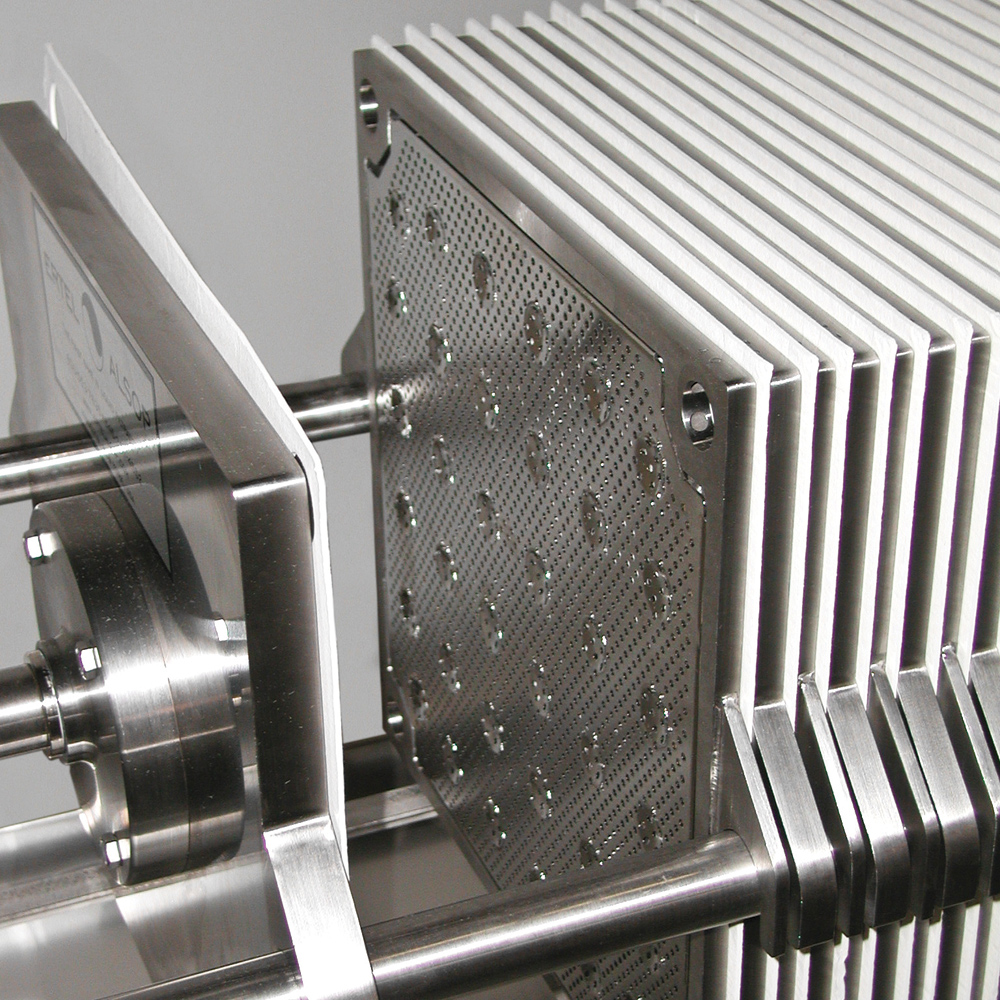

One of the defining features of ErtelAlsop’s design is the internally ported plate. Unlike external porting, which often relies on gaskets that can degrade or cause compatibility issues, the internal port design uses the filter media itself as the gasket.

- No Gaskets Required: Eliminates concerns over O-ring compatibility and reduces maintenance costs.

- Sanitary Operation: Without O-rings to trap product, the risk of cross-contamination between batches is significantly reduced.

- Media Versatility: Accommodates a broad range of filter media materials and thicknesses, including pads, paper, and cloth.

Product Series Overview

ErtelAlsop offers improved scalability through various series designed for specific volume requirements, from laboratory R&D to full-scale industrial production.

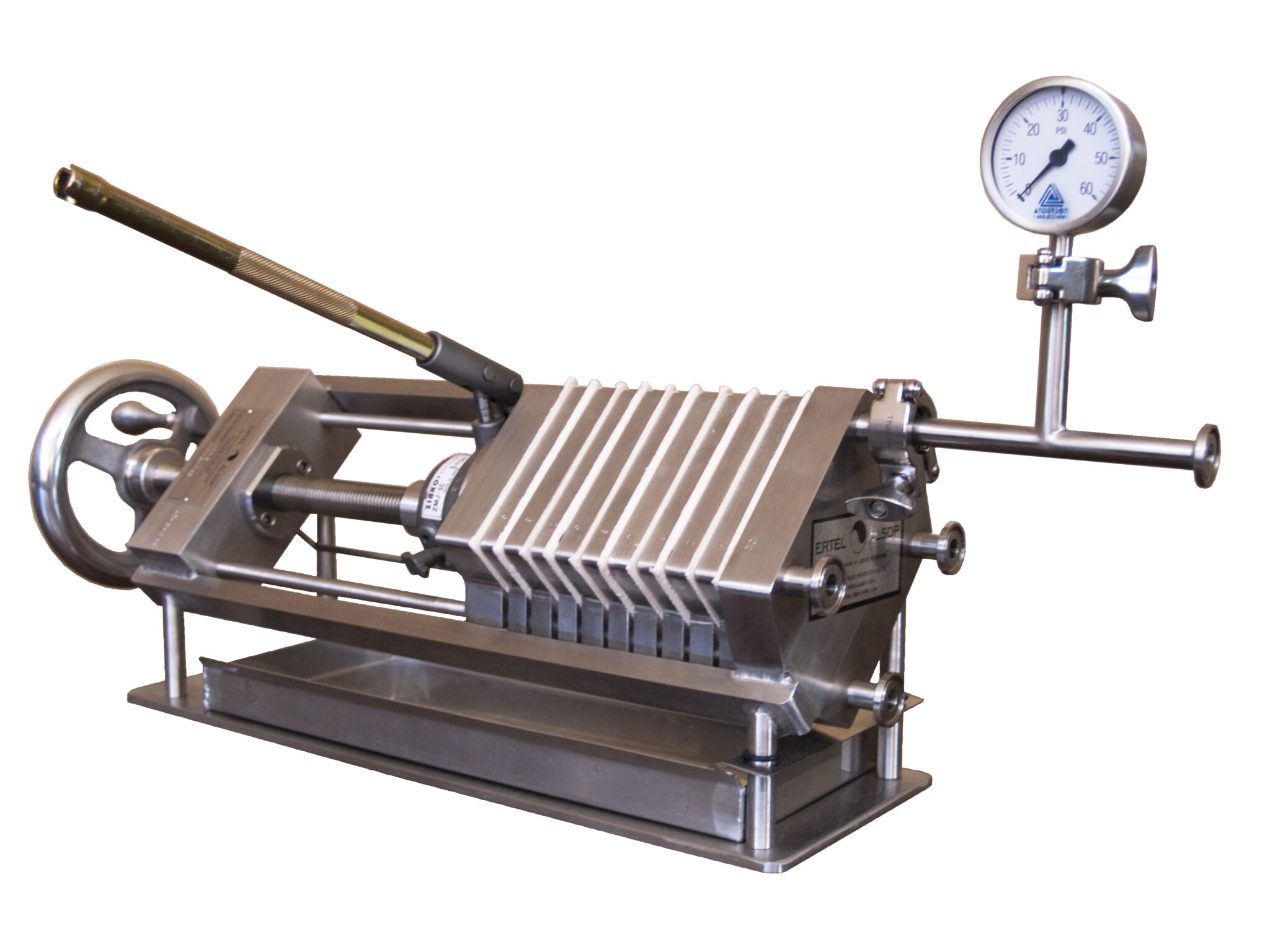

1. Diamond Series (Laboratory & Pilot)

Designed for critical applications where high-value liquid recovery is essential, the Diamond Series minimizes hold-up volume. Traditional presses may lose up to 90% of remaining liquid after a cycle; the Diamond design eliminates this obstacle, ensuring maximum yield.

| Model | Plate Size | Ideal Application | Key Feature |

|---|---|---|---|

| 4D | 4-inch | R&D, Pilot Testing | Bench-top mounted, accepts 20 pads |

| 8D | 8-inch | Small Batch Production | Economical, ultra-fine filtration |

| 12D | 12-inch | Pilot / Small Production | Cart-mounted, accepts up to 50 pads |

2. Letre Series (Large Volume)

For large-scale operations, the Letre Series (24″ and 36″ square plates) serves as the industry standard. These units are built for high-volume cake accumulation and efficient washing, allowing operators to recover valuable product from the filter cake.

Technical Specifications: Letre Series

The following table outlines the capabilities of the commercial-grade Letre filters, which support large batch sizes and high flow rates.

| Specification | Letre 604 | Letre 910 |

|---|---|---|

| Plate Dimension | 24 in (610 mm) | 36 in (914.5 mm) |

| Filtration Area per Sheet | 3.6 ft² (0.33 m²) | 7.26 ft² (0.67 m²) |

| Ports | 4 Internal | 4 Internal |

| Batch Size Capacity | Up to 13,200 gal (50,000 L) | Up to 13,200 gal (50,000 L) |

| Cake Vol (50mm inlet) | 3.98 gal (15.06 L) | 9.62 gal (36.40 L) |

Key Applications

The versatility of plate and frame filters makes them suitable for a wide variety of industries. The ability to vary inlet frame thickness allows for the collection of high sludge volumes, while the use of BioClean™ plates ensures sanitary compliance.

- Pharmaceuticals: Critical depth filtration for biologics, small volume parenterals, and blood fractions.

- Food & Beverage: Clarification of fruit juices, distilled spirits, wine, and removal of haze/particulates in syrups.

- Cosmetics: Filtration of fragrances, essential oils, and lotions, ensuring crystal-clear aesthetics and product stability.

- Chemical: Efficient cake washing and recovery of valuable chemical solids.

Why Choose Plate and Frame Technology?

Despite being a foundational technology, the plate and frame press remains one of the most cost-effective filtration methods per unit of fluid processed. Its primary economic benefit lies in product recovery. Through efficient cake washing, operators can reclaim valuable liquid product that would otherwise be lost in the solid waste, or conversely, wash proper product solids free of impurities.

Purecowater is equipped to assist you in determining the correct equipment sizing, media selection, and configuration for your specific process stream.

For more information on how to integrate ErtelAlsop filtration solutions into your facility, please reach out to our team.