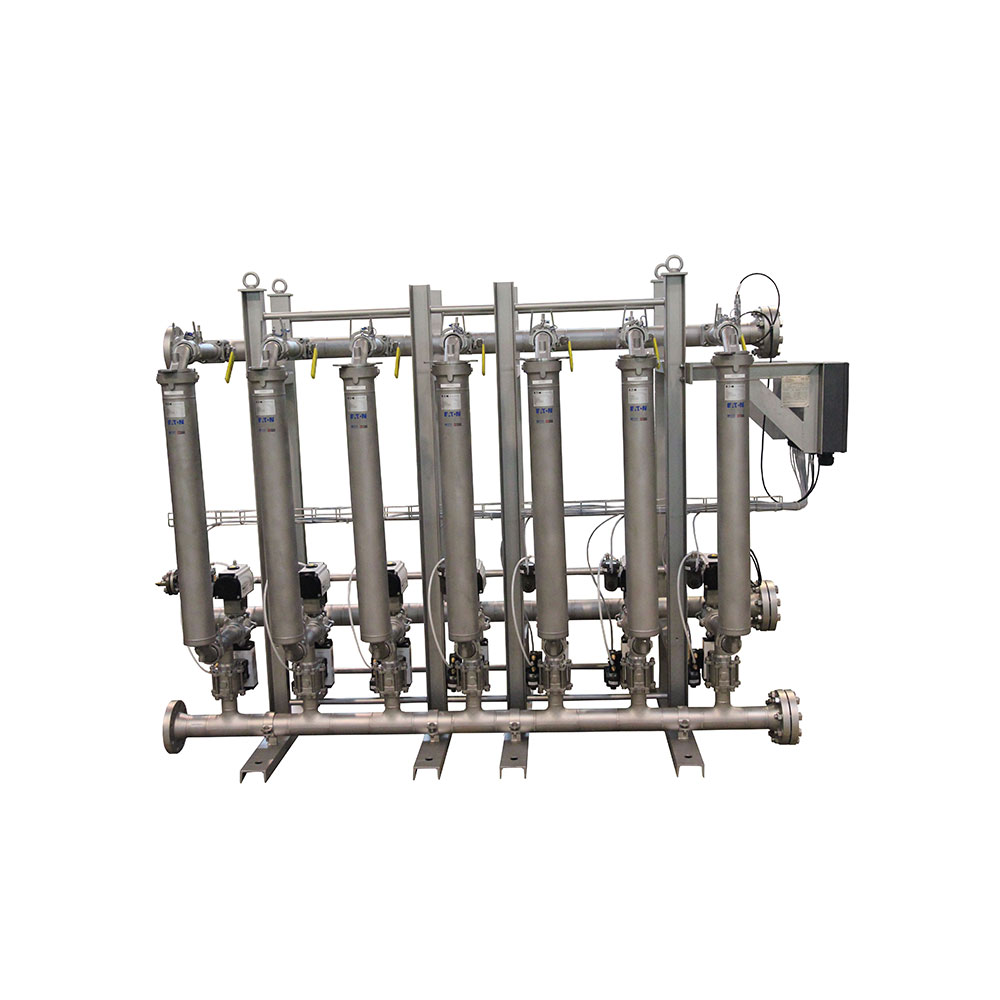

High-Pressure, Automated Filtration for Demanding Applications

The Eaton AFC Series Tubular Backwash Filter stands out as a premier solution for industrial applications requiring robust, high-pressure filtration with minimal maintenance. Engineered to handle pressures up to 1,000 psi (69 bar), this system is designed for versatility, capable of filtering low-viscosity fluids with a retention range from 1 to 1,700 microns.

At Purecowater, we supply the AFC Series to industries ranging from pulp and paper to chemical processing, ensuring continuous flow and superior contaminant removal.

How It Works: Efficient Self-Cleaning Technology

The AFC Series utilizes a tubular design that optimizes flow dynamics and cleaning efficiency. The permanent filter media removes solid contaminants from the process liquid. When the system requires cleaning, it initiates an automated backwashing sequence.

One of the key advantages of the AFC Series is its ability to clean the filter media one tube at a time (in multiplex configurations) or via a specific backwash cycle, ensuring that downstream flow is often maintained or minimally impacted. The system is available in two primary backwashing configurations:

- Internal Backwash: Utilizes the process fluid itself to clean the elements. This is ideal for standard applications where a small percentage (<2%) of the product can be used for cleaning.

- External Backwash: Uses a separate clean water source or filtrate for cleaning. This is essential for valuable fluids, hazardous liquids, or applications with low operating pressures (below 45 psi).

Core Features and Benefits

The AFC Series is packed with features designed to reduce operational costs and downtime:

- High-Pressure Capability: The AFC-2200 model specifically supports operation up to 1,000 psi, making it unique in the market for high-pressure water loops.

- ACCUFLUX Media: Available with ACCUFLUX elements that dramatically increase the filter surface area within the same footprint, enhancing capacity.

- Quick Access: The simple design and quick-coupler valve connectors allow for rapid element access and body tube removal without special tools.

- Automated Operation: Proprietary 3-way ball valves on AFC-1100 multiplex filters allow for fast sequencing and maximum cleaning force.

- Scalability: Available in Single, Duo, and Multiplex configurations to handle flow rates up to 3,000 gpm (681 m³/hr) in a single system.

Technical Specifications

The following table outlines the capabilities across the different models in the AFC family.

| Feature | AFC-1100 | AFC-1500 | AFC-2200 | AFC-3300 |

|---|---|---|---|---|

| Body Inlet/Outlet | 1″ (25 mm) | 1.5″ (38 mm) | 2″ (51 mm) | 3″ (76 mm) |

| Max Pressure Rating | 250 psi | 250 psi | 1,000 psi | 150 psi |

| Micron Retention | 1 to 1,700 microns | |||

| Element Style | 2″ dia. single | 2.25″ dia. single | 3.25″ dia., Tri-Cluster, Accuflux-7 | 3.25″ dia., Tri-Cluster, Accuflux-7 |

| Backwash Volume | <2% System Vol | <2% System Vol | <2% System Vol | <2% System Vol |

Common Applications

Thanks to its versatile media options and high-pressure ratings, the Eaton AFC Series is successfully deployed in a wide variety of sectors:

- Industrial Water: City water lines, fresh water intake, and chiller water.

- Pulp & Paper: White water, shower water, and paper coating wet end starch.

- Food & Beverage: CIP (Clean-in-Place) fluids and hot condensate.

- Manufacturing: Pelletizer water and machine coolants.

Contact Purecowater

Whether you need a single unit for a specific line or a complex multiplex system for high-flow requirements, Purecowater can assist with sizing, selection, and procurement of the Eaton AFC Series.