Advanced Desalination with LG Seawater RO Membranes

At Purecowater, we pride ourselves on distributing the most advanced filtration technologies available on the market. Among our premier offerings are LG Chem’s Seawater Reverse Osmosis (SWRO) membranes. Incorporating innovative Thin Film Nanocomposite (TFN) technology, these membranes are engineered to tackle the toughest desalination challenges while optimizing energy efficiency and permeate quality.

Whether you are operating a large-scale municipal desalination plant or an industrial water treatment facility, understanding the capabilities of LG’s NanoH2O™ technology can significantly impact your operational costs and water quality output.

The Technology: Thin Film Nanocomposite (TFN)

Unlike conventional Reverse Osmosis membranes, LG Chem utilizes Thin Film Nanocomposite (TFN) technology. This proprietary approach incorporates benign nanomaterials into the thin-film polyamide layer of the membrane. The result is a substantial increase in permeability without compromising salt rejection.

Key Performance Benefits:

- Higher Flux: Delivers up to 20% more flow compared to conventional technologies at the same pressure.

- Superior Rejection: Industry-leading salt rejection rates (up to 99.89%), ensuring high-purity permeate even from high-salinity feedwaters.

- Energy Efficiency: The high permeability allows plants to operate at lower feed pressures, directly reducing energy consumption.

- Boron Removal: Enhanced boron rejection capabilities, critical for agricultural and drinking water standards.

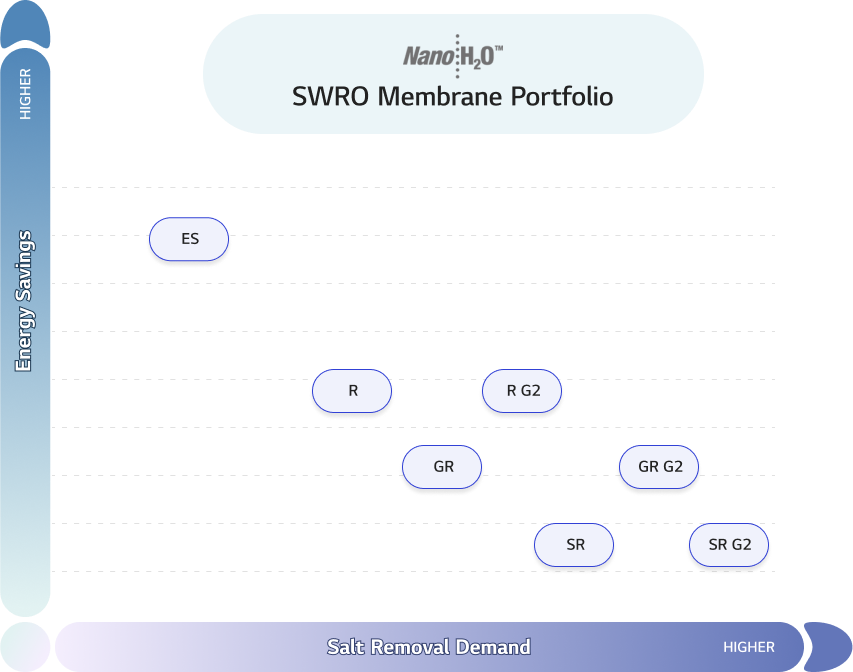

SWRO Product Line Snapshot

LG Water Solutions divides their Seawater RO membranes into specific series designed to meet different operational priorities, such as maximum rejection, energy saving, or fouling resistance.

1. High Rejection Series (R / G2)

The LG SW 400 R G2 and LG SW 440 R G2 are the flagship models for facilities requiring the highest quality permeate. These are ideal for warm water applications or where stringent water quality standards must be met.

2. High Flow / Energy Saving Series (ES)

For operations focused on reducing Operational Expenditure (OPEX), the ES series provides high permeability, allowing for lower pressure operation and significant energy savings.

3. Anti-Fouling Series (GR / SR)

Models like the LG SW 400 GR feature improved fouling resistance, often utilizing a thicker feed spacer (34 mil) to reduce the pressure drop and frequency of cleaning in challenging feedwater conditions.

Technical Specifications & Comparison

Below is a detailed comparison of popular LG SWRO membrane elements available through Purecowater.

| Product Model | Active Area (ft²) | Permeate Flow (GPD) | Salt Rejection (%) | Boron Rejection (%) | Feed Spacer (mil) |

|---|---|---|---|---|---|

| LG SW 400 R G2 | 400 | 9,000 | 99.88% | 93% | 34 |

| LG SW 440 R G2 | 440 | 9,900 | 99.88% | 93% | 28 |

| LG SW 400 SR G2 | 400 | 6,000 | 99.89% | 93% | 34 |

| LG SW 400 GR | 400 | 7,500 | 99.85% | 93% | 34 |

| LG SW 400 ES | 400 | 6,800 | 99.60% | 81% | 34 |

*Standard test conditions: 32,000 ppm NaCl, 5 ppm Boron, 800 psi (55 bar), 25°C, pH 8, 8% recovery. Performance may vary based on operating conditions.

Operating Specifications for System Design

Integrating these membranes into your RO system requires adherence to specific operating limits to ensure longevity and warranty compliance.

- Max. Operating Pressure: 1,200 psi (82.7 bar)

- Max. Operating Temperature: 45°C (113°F)

- pH Range (Continuous): 2–11

- pH Range (Cleaning): 2–13

- Max. Feedwater SDI (15 min): 5.0

- Max. Feedwater Turbidity: 1.0 NTU

Ideal Applications

All LG SWRO membranes are designed for heavy-duty industrial and municipal applications. Common use cases include:

- Municipal Desalination: Producing potable water from seawater sources.

- Power Generation: Creating high-purity makeup water for boilers.

- Industrial Process Water: Serving petrochemical, mining, and semiconductor industries.

- Resorts and Marine: Reliable water production for island resorts and marine vessels.

Why Choose Purecowater?

As a distributor and OEM, Purecowater does more than just ship parts. We help you engineer solutions. Whether you need a replacement schedule for your current membranes or are designing a membrane system from the ground up, we have the technical expertise to guide you to the right LG Water Solutions product.

Ready to optimize your rejection rates and lower your energy costs?